Welcome to the jeepExperts.com in-depth web page on WJ Generation Jeep Grand Cherokee cooling system service. We have organized as a lot data as we may discover right into a useful article under. Is one thing incorrect or lacking? Please get in contact with us and we’ll repair it!

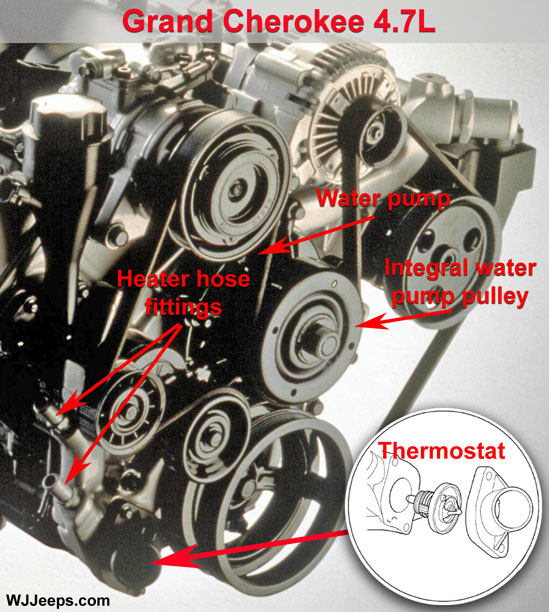

1999 Jeep Grand Cherokee 4.7L V-8 Engine. J-912

1999 Jeep Grand Cherokee 4.7L V-8 Engine. J-912Thermostats

Both the 4.0L and 4.7L engines use 195° thermostats for all mannequin years from 1999-2004. When changing a thermostat it is vitally essential to put in one with the identical temperature ranking (the one exception is likely to be with sure efficiency modifications or chips that suggest or require a special temperature thermostat). No advantages or efficiency beneficial properties may be realized by putting in a “cooler” thermostat right into a inventory engine. Doing so shouldn’t be really helpful, it provides you with colder warmth within the winter and will intervene with engine efficiency.

A thermostat rated decrease than the manufacturing unit thermostat will richen your gasoline combination a bit on the expense of gasoline mileage, elevated exhaust emissions and dirtying your oil sooner – to not point out shortening the lifetime of your cylinder partitions and catalytic converters and extra frequent spark plug modifications. The unnoticeable efficiency acquire, if any in any respect, is just not definitely worth the potential drawbacks.

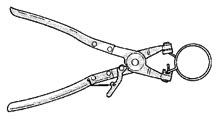

Radiator hose clamps

The cooling system makes use of each worm drive and spring sort hose clamps. If a spring sort clamp substitute is important, substitute with the unique Mopar tools spring sort clamp.

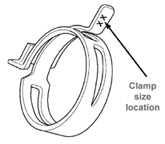

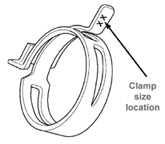

CAUTION: A quantity or letter is stamped into the tongue of fixed rigidity clamps. If substitute is important, use solely a unique tools clamp with matching quantity or letter. See picture under.

The worm sort hose clamp makes use of a specified torque worth to keep up correct rigidity on a hose connection. The spring sort hose clamp applies fixed rigidity on a hose connection.

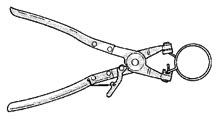

WARNING: CONSTANT TENSION HOSE CLAMPS ARE USED ON MOST COOLING SYSTEM HOSES. WHEN REMOVING OR INSTALLING, USE ONLY TOOLS DESIGNED FOR SERVICING THIS TYPE OF CLAMP, SUCH AS SPECIAL CLAMP TOOL MILLER p/n 8495A. SNAP-ON CLAMP TOOL p/n HCP20 MAY BE USED FOR LARGER CLAMPS. ALWAYS WEAR SAFETY GLASSES WHEN SERVICING CONSTANT TENSION CLAMPS. A NUMBER OR LETTER IS STAMPED INTO THE TONGUE OF CONSTANT TENSION CLAMPS. IF REPLACEMENT IS NECESSARY, USE ONLY AN ORIGINAL EQUIPMENT CLAMP WITH MATCHING NUMBER OR LETTER.

Radiator hose fixed rigidity clamp – dimension location

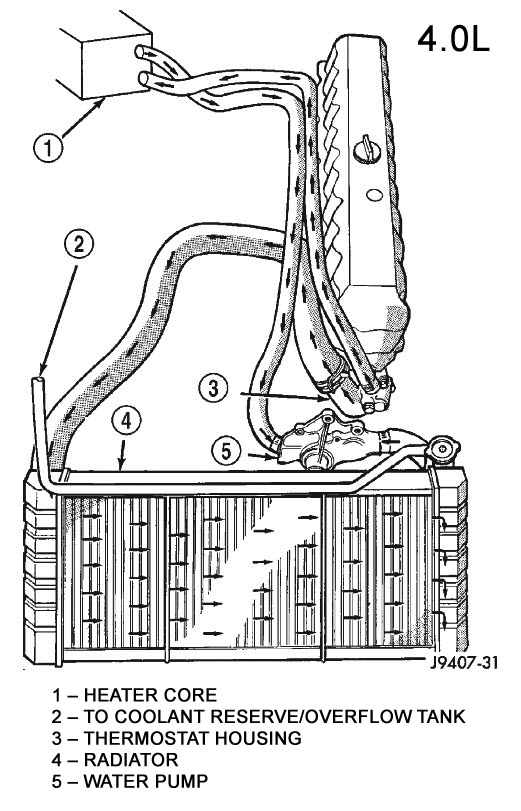

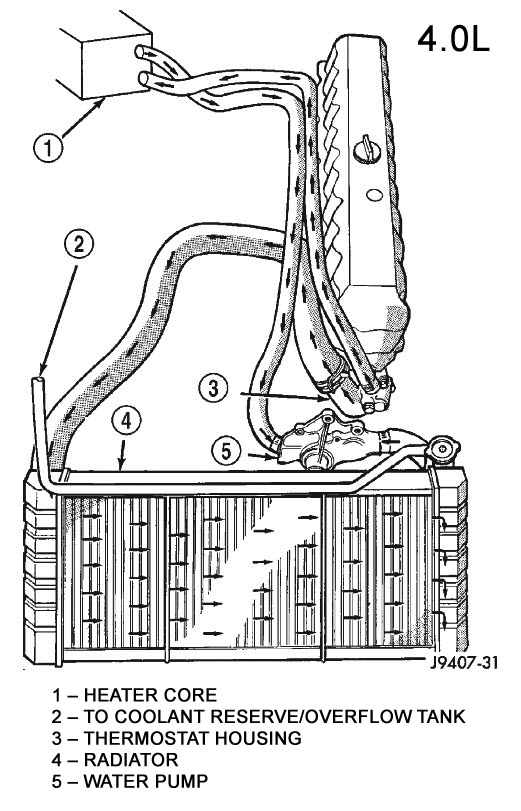

4.0L engine – Draining the cooling system

WARNING: DO NOT REMOVE THE CYLINDER BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR DRAINCOCK WITH SYSTEM HOT AND UNDER PRESSURE. SERIOUS BURNS FROM COOLANT CAN OCCUR.

1. DO NOT take away radiator cap first. With engine chilly, find radiator draincock on the fitting decrease facet of radiator going through to rear of auto.

2. Attach one finish of a hose to the draincock. Put the opposite finish right into a clear container. Open draincock and drain coolant from radiator. This will empty the coolant reserve/overflow tank. The coolant doesn’t must be faraway from the tank except the system is being refilled with a recent combination. When tank is empty, take away radiator cap and proceed draining cooling system. To drain the engine block of coolant, take away the cylinder block drain plug, situated on the facet of cylinder block under the exhaust manifold.

4.0L engine – refilling the cooling system

Coolant suggestions and cautions:

The really helpful combination is 50/50 ethylene-glycol and low mineral content material water. Never use pure antifreeze. Only Mopar Antifreeze Coolant, 5 Year/100,000 Mile Formula (glycol base coolant with corrosion inhibitors known as HOAT) is really helpful. This coolant gives the most effective engine cooling with out corrosion when blended with 50% distilled water.

Antifreeze combination should at all times be not less than 44%, all climates 12 months spherical. Maximum safety (-90d) is supplied with a 68% combination safety. If the share is decrease than 44 p.c, engine elements could also be eroded by cavitation, and cooling system elements could also be severely broken by corrosion.

CAUTION: Mopar Antifreeze/Coolant, 5 Year/100,000 Mile Formula (MS-9769) will not be blended with every other sort of antifreeze. Mixing of coolants apart from specified (non-HOAT or different HOAT), could lead to engine harm that will not be lined beneath the brand new car guarantee, and decreased corrosion safety.

CAUTION: Do not use coolant components which might be claimed to enhance engine cooling.

4.0L coolant capability:

1999-2000: 13.0 qts. (together with 2.3 qts. for resevoir)

2001-2004: 15.0 qts. (together with 1 qt. for resevoir)

1. Tighten the radiator draincock and the cylinder block drain plug(s) (if eliminated).

2. Fill system utilizing a 50/50 combination of ethyleneglycol antifreeze and low mineral content material water. Fill radiator to high and set up radiator cap. Add ample coolant to the reserve/overflow tank to boost degree to FULL mark.

3. With heater management unit within the HEAT place, function engine with radiator cap in place.

4. After engine has reached regular working temperature, shut engine off and permit it to chill. When engine is cooling down, coolant will likely be drawn into the radiator from the reserve/overflow tank.

5. Add coolant to order/overflow tank as needed. Only add coolant to the reserve/overflow tank when the engine is chilly. Coolant degree in a heat engine will likely be greater as a consequence of thermal growth. To purge the cooling system of all air, this warmth up/quiet down cycle (including coolant to chilly engine) should be carried out thrice. Add needed coolant to boost tank degree to the FULL mark after every quiet down interval.

4.0L engine – Adding further coolant

The use of aluminum cylinder blocks, cylinder heads and water pumps requires particular corrosion safety. Only Mopart Antifreeze/Coolant, 5 Year/100,000 Mile Formula (glycol base coolant with corrosion inhibitors known as HOAT, for Hybrid Organic Additive Technology) is really helpful. This coolant gives the most effective engine cooling with out corrosion when blended with 50% distilled water to acquire to acquire a freeze level of -35°F (-37°C). If it loses colour or turns into contaminated, drain, flush, and substitute with recent correctly blended coolant answer.

CAUTION: Do not use coolant components which might be claimed to enhance engine cooling.

4.7L engine – Draining the cooling system

WARNING: DO NOT REMOVE THE CYLINDER BLOCK DRAIN PLUGS OR LOOSEN THE RADIATOR DRAINCOCK WITH SYSTEM HOT AND UNDER PRESSURE. SERIOUS BURNS FROM COOLANT CAN OCCUR.

1. DO NOT take away radiator cap first. With engine chilly, find radiator draincock on the left decrease facet of radiator going through to rear of auto.

2. Attach one finish of a hose to the draincock. Put the opposite finish right into a clear container. Open draincock and drain coolant from radiator. This will empty the coolant reserve/overflow tank. The coolant doesn’t must be faraway from the tank except the system is being refilled with a recent combination. When tank is empty, take away radiator cap and proceed draining cooling system. To drain the engine block of coolant, take away the cylinder block drain plug, situated on the facet of cylinder block under the exhaust manifold.

4.7L engine – refilling the cooling system and including further coolant

Coolant suggestions and cautions:

The really helpful combination is 50/50 ethylene-glycol and low mineral content material water. Never use pure antifreeze. Only Mopar Antifreeze Coolant, 5 Year/100,000 Mile Formula (glycol base coolant with corrosion inhibitors known as HOAT) is really helpful. This coolant gives the most effective engine cooling with out corrosion when blended with 50% distilled water.

Antifreeze combination should at all times be not less than 44%, all climates 12 months spherical. Maximum safety (-90d) is supplied with a 68% combination safety. If the share is decrease than 44 p.c, engine elements could also be eroded by cavitation, and cooling system elements could also be severely broken by corrosion.

CAUTION: Mopar Antifreeze/Coolant, 5 Year/100,000 Mile Formula (MS-9769) will not be blended with every other sort of antifreeze. Mixing of coolants apart from specified (non-HOAT or different HOAT), could lead to engine harm that will not be lined beneath the brand new car guarantee, and decreased corrosion safety.

CAUTION: Do not use coolant components which might be claimed to enhance engine cooling.

4.7L coolant capability:

1999-2000: 13.0 qts. (together with 2.3 qts. for resevoir)

2001-2004: 14.5 qts. (together with 1 qt. for resevoir)

1. Tighten the radiator draincock and the cylinder block drain plug(s) (if eliminated).

CAUTION: Failure to purge air from the cooling system may end up in an overheating situation and extreme engine harm.

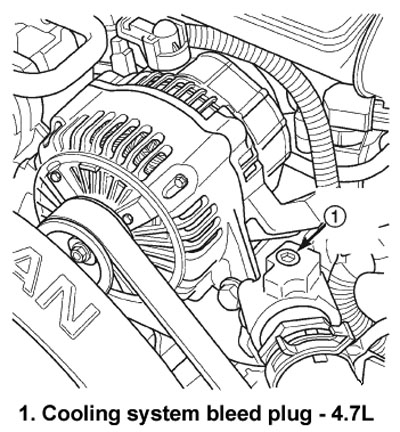

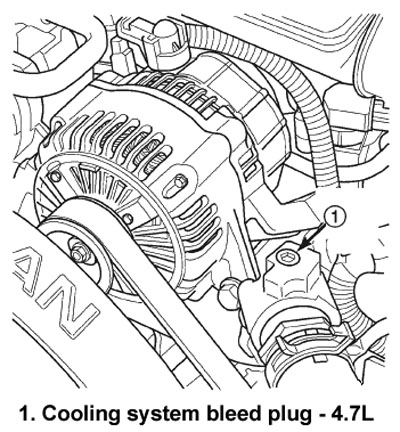

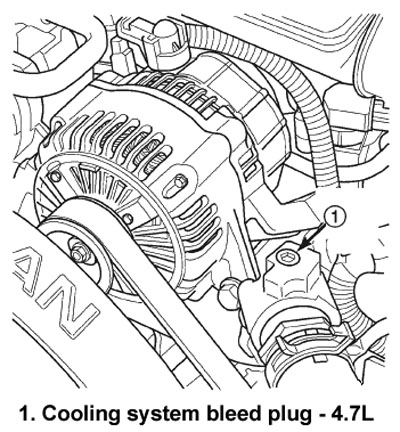

2. Remove the cooling system bleed plug from the radiator higher hose inlet housing (see photograph under for plug location). Fill system utilizing a 50/50 combination of ethylene-glycol antifreeze and low mineral content material water, till coolant begains popping out of the cooling system bleed gap. Install the cooling system bleed plug. Fill radiator to high and set up radiator cap. Add ample coolant to the reserve/overflow tank to boost degree to FULL mark.

3. With heater management unit within the HEAT place, function engine with radiator cap in place.

4. After engine has reached regular working temperature, shut engine off and permit it to chill. When engine is cooling down, coolant will likely be drawn into the radiator from the reserve/overflow tank.

5. Add coolant to order/overflow tank as needed. Only add coolant to the reserve/overflow tank when the engine is chilly. Coolant degree in a heat engine will likely be greater as a consequence of thermal growth. To purge the cooling system of all air, this warmth up/quiet down cycle (including coolant to chilly engine) should be carried out thrice. Add needed coolant to boost tank degree to the FULL mark after every quiet down interval.

4.0L and 4.7L – Cooling system reverse flushing

CAUTION: The cooling system usually operates at 14 to 18 psi (97 to 124 kPa) stress. Exceeding this stress could harm the radiator or hoses.

Reverse flushing of the cooling system is the forcing of water by way of the cooling system. This is completed utilizing air stress in the wrong way of regular coolant circulation. It is normally solely needed with very soiled techniques with proof of partial plugging.

Chemical cleansing

If visible inspection signifies the formation of sludge or scaly deposits, use a radiator cleaner (Mopar Radiator Kleen or equal) earlier than flushing. This will soften scale and different deposits and assist the flushing operation.

CAUTION: Be positive directions on the container are adopted

Reverse flushing the radiator

Disconnect the radiator hoses from the radiator fittings. Attach a piece of radiator hose to the radiator backside outlet becoming and insert the flushing gun. Connect a water provide hose and air provide hose to the flushing gun.

CAUTION: The cooling system usually operates at 14 to 18 psi (97-to-124 kPa) stress. Exceeding this stress could harm the radiator or hoses.

Allow the radiator to fill with water. When radiator is stuffed, apply air in brief blasts permitting radiator to refill between blasts. Continue this reverse flushing till clear water flows out by way of rear of radiator cooling tube passages. For extra data, check with working directions provided with flushing tools. Have radiator cleaned extra extensively by a radiator restore store.

Reverse flushing the engine

Drain the cooling system (as described above). Remove the thermostat housing and thermostat. Install the thermostat housing. Disconnect the radiator higher hose from the radiator and fix the flushing gun to the hose. Disconnect the radiator decrease hose from the water pump. Attach a lead away hose to the water pump inlet becoming.

CAUTION: Be positive that the heater management valve is closed (warmth off). This is completed to stop coolant circulation with scale and different deposits from getting into the heater core.

Connect the water provide hose and air provide hose to the flushing gun. Allow the engine to fill with water. When the engine is stuffed, apply air in brief blasts, permitting the system to fill between air blasts. Continue till clear water flows by way of the lead away hose. For extra data, check with working directions provided with flushing tools.

Remove the lead away hose, flushing gun, water provide hose and air provide hose. Remove the thermostat housing. Install the thermostat and housing with a substitute gasket. Connect the radiator hoses. Refill the cooling system with the proper antifreeze/water combination as described above.

4.0L engine – Thermostat removing

WARNING: DO NOT LOOSEN THE RADIATOR DRAINCOCK WITH THE SYSTEM HOT AND PRESSURIZED. SERIOUS BURNS FROM THE COOLANT CAN OCCUR.

1. Drain the coolant from the radiator till the extent is under the thermostat housing. Do not waste reusable coolant. If the answer is clear, drain the coolant right into a clear container for reuse.

2. Remove radiator higher hose and heater hose at thermostat housing. See cautions above for eradicating radiator hose clamps.

3. Disconnect wiring connector at engine coolant temperature sensor.

4. Remove thermostat housing mounting bolts, thermostat housing, gasket and thermostat. Discard outdated gasket.

5. Clean the gasket mating surfaces.

WARNING: CONSTANT TENSION HOSE CLAMPS ARE USED ON MOST COOLING SYSTEM HOSES. WHEN REMOVING OR INSTALLING, USE ONLY TOOLS DESIGNED FOR SERVICING THIS TYPE OF CLAMP, SUCH AS SPECIAL CLAMP TOOL MILLER p/n 8495A. SNAP-ON CLAMP TOOL p/n HCP20 MAY BE USED FOR LARGER CLAMPS. ALWAYS WEAR SAFETY GLASSES WHEN SERVICING CONSTANT TENSION CLAMPS. A NUMBER OR LETTER IS STAMPED INTO THE TONGUE OF CONSTANT TENSION CLAMPS. IF REPLACEMENT IS NECESSARY, USE ONLY AN ORIGINAL EQUIPMENT CLAMP WITH MATCHING NUMBER OR LETTER.

4.0L engine – Thermostat set up

1. Install the substitute thermostat in order that the pellet, which is encircled by a coil spring, faces the engine. All thermostats are marked on the outer flange to point the right put in place.

(a) Observe the recess groove within the engine cylinder head.

(b) Position thermostat in groove with arrow and air bleed gap on outer flange pointing up.

2. Install substitute gasket and thermostat housing.

CAUTION: Tightening the thermostat housing erratically or with the thermostat out of its recess, could lead to a cracked housing.

3. Tighten the housing bolts to 16 ft. lbs. (22 N·m) torque.

4. Install hoses to thermostat housing.

5. Install electrical connector to coolant temperature sensor.

6. Be positive that the radiator draincock is tightly closed. Fill the cooling system to the proper degree with the required coolant combination. See refill directions above.

7. Start and heat the engine. Check for leaks.

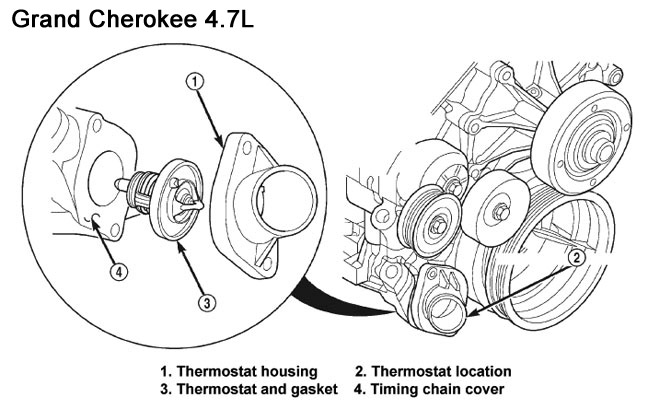

4.7L engine – Thermostat removing

WARNING: DO NOT LOOSEN RADIATOR DRAINCOCK WITH SYSTEM HOT AND PRESSURIZED. SERIOUS BURNS FROM COOLANT CAN OCCUR.

1. Disconnect detrimental battery cable at battery.

2. Drain cooling system. Do not waste reusable coolant. If answer is clear, drain coolant right into a clear container for reuse. If thermostat is being changed, make certain that substitute is specified thermostat for car mannequin and engine sort.

3. Remove splash protect.

4. Remove decrease radiator hose clamp and decrease radiator hose at thermostat housing. See cautions above for eradicating radiator hose clamps.

5. Remove thermostat housing mounting bolts, thermostat housing and thermostat.

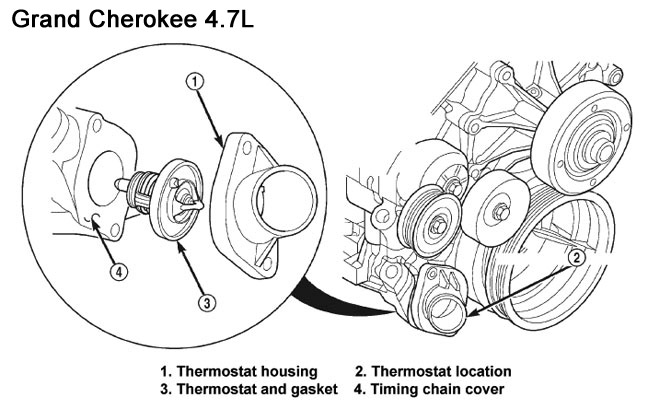

4.7L engine – Thermostat set up

1. Clean mating areas of timing chain cowl and thermostat housing.

2. Install thermostat (spring facet down) into recessed machined groove on timing chain cowl.

3. Position thermostat housing on timing chain cowl.

4. Install two housing-to-timing chain cowl bolts. Tighten bolts to 115 in. lbs. (13 N·m) torque.

CAUTION: Housing should be tightened evenly and thermostat should be centered into recessed groove in timimg chain cowl. If not, it might lead to a cracked housing, broken timing chain cowl threads or coolant leaks.

5. Install decrease radiator hose on thermostat housing.

6. Install splash protect.

7. Be positive that the radiator draincock is tightly closed. Fill cooling system. See refill directions above.

8. Connect detrimental battery cable to battery.

9. Start and heat the engine. Check for leaks.

WJ Thermostat elements 1999-2004 |

|||

| 4.0L | ThermostatGasket

Housing |

52028186AB53020547AB

53006192 |

$6.20$2.10

$13.70 |

| 4.7L | Thermostat & gasketHousing | 52079476AB53020887AB | $26.60$14.50 |